I've been making observations and taking notes since performing the "rough" timing yesterday and here's what found: The engine idles at 1,500 rpm from a cold start. That's 1,500 from the car's tachometer ... which could be a bit off. Idle doesn't sound blaring loud though, rather a pleasing deep old Volvo like rumble ... or old school bus like! Anyways, idle drops to 1,000 rpm at around the 6 minute mark presumably from the engine warming up and the Auxilary Air Valve (AAV) closing down and restricting air to bring the idle down (as it should). At around 7 minutes, the idle starts to stutter and the engine soon stalls.

First off, 6 minutes before the engine warms up and idle drops seems a tad long I think ... but who knows, maybe that's normal? Second observation is at the time the idle starts to drop, the fumes from the tail pipe begin to smell like gasoline ... that and my eyes start to water. This has been pretty consistent since the first day the car started acting up. Me thinks, during a cold start with the engine still cold and the AAV open, there's plenty of air to burn off the fuel. As the engine warms-up and the AAV closes, less air gets through leading to incomplete combustion of fuel. Run the engine long enough (7 minute mark) and it soon stalls from air starvation compared to the amount of fuel being served, and finally there's enough fuel left over to flood the engine to prevent a subsequent warm or hot start until the excess fuel evaporates.

Well ... I did some reading, and learned a new word: "running rich" - when there's a high fuel-to-air ratio in the chambers ... exactly what I'm experiencing! And I though it meant hanging out with the golfers at the country club in the good side of town ... no that's "running with the rich" ... nevermind. Here's another tell-tale sign of running with a rich mixture: black sooty fouled plugs (pictured below). These are brand new spark plugs by the way!

Fouled Spark Plug:

| Crankcase Breather Hose:

|

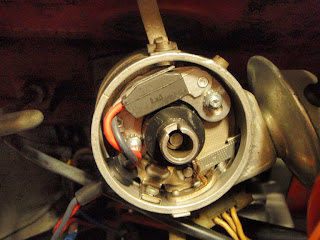

Now, armed with this new clue and a set of quantitative base-line data to compare against (specifically the elapsed time before things start to go south), I think my next move ought to be resetting the timing followed by checking the fuel pressure. Even though the "rough" timing I did sounds good to me (then again, any signs of life from this Volvo excites me), I think proper static timing is called for this time as incorrect ignition timing could also lead to rich running conditions from what I read. Correct fuel pressure is also critical as higher than normal fuel pressure also leads to running rich. I'll take on these two tasks next weekend as I need to consult my horoscope and purchase a fuel pressure gauge.

While messing around with the crankcase hoses checking for vacuum leaks, I noticed that the hose from the oil filler cap to the intake manifold had some mayonnaise like residue in it (pictured above). Not sure if this is normal. What is this stuff ... engine pus? In any case, I replaced the crankcase hoses with fresh ones. Some of the crankcase hoses also didn't have hose clamps on the ends and stock photos of the hoses didn't show any on them either, but I clamped all of them up anyway just to be rid of any potential vacuum leaks that might be contributing to the problem.

Crankcase Hose Nipple - Before:

| Crankcase Hose Nipple - After:

|

The crankcase hose from the oil filler cap to the manifold attaches to a nipple which I also removed and cleaned as pictured ablove. I used a port brush for a hummingbird feeder to get the insides real good, and flushed out lots of black carbon deposits, and finally finished it off with some light sanding with the rotary tool to get rid of years of surface oxidation. In summary, none of the changes I did today made any difference to the warm engine stalling problem. I'm still checking things off my list, but I have hopes for next week as I attempt to dial in the timing a few notches better and check the fuel pressure.

Oh ... I told myself that I'm not going to be one of those people who name their cars, but after what I had to go through this past few weekends, I've changed my mind and am naming it "Legion" ... for the problems are many.